Function overview

Calibration |

|

|---|---|

Functions |

Description |

➢Differential pressure adjustment |

Differential pressure adjustment by the customer A pressure adjustment can be done by the customer. The following options are available: oAcquisition of 1 to 9-point differential pressure reference points oZero point compensation – see below oReset to the factory adjustment.

IMPORTANT: oA new adjustment or a reset to the factory adjustment cause a loss of any customer adjustment before. oThe customer should take care that the differential pressure applied at the probe and the reference is stable before acquisition. Please take into account, that short time variations of the measured differential pressure values of the reference and the probe within standard measurement interval could influence the accuracy of the acquired data and the whole adjustment process. Therefore the data acquisition of the reference and the probe values need to be done in real time to each other. For that reason the RMS-Config SW and an AC3001-XD cable (USB adapter to a PC) is recommended for an adjustment setup and process.

Zero point compensation (PCD-S-Mxx): For the probes with membrane sensor (PCD-S-Mxx), the zero point compensation is realized doing a 1-point adjustment with a reference value of 0 Pa using a short pipe connected directly between "+" and "-". It compensates a constant deviation (offset over the complete range) caused by sensor drift or system deviations. For maximum accuracy, Rotronic recommends strongly to perform a zero point compensation after the installation and initial operation and to repeat it annually. For aggressive environments / gas media a more frequent zero point compensation advised. The RMS SW or the RMS-Config SW is to be used for the zero point compensation. Please acquire only one reference value (0 Pa) and adjust. For more information – see the related SW manuals.

Zero point compensation (PCD-S-Fxx): The probes with the flow-based sensors (PCD-S-Fxx), the zero point compensation is integrated automatically at the sensor. |

➢Simulator mode |

The measured differential pressure value of the probe can be replaced by a fixed value for setup reason of the RMS system. In this case, the value is marked as a "Simulator" as the RMS SW. |

➢Filter |

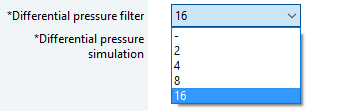

The differential pressure probe has a low pass filter included to reduce noise on the measured value. Possible values are 0, 2, 4, 8, 16 (default). The value represents the number of measurements, which create the basis for the measurement filter (average calculation). This measurement and its average calculation is done in less than 100 milliseconds and within every measurement interval. Due to the fast measurement, we advise to use the maximum filter of 16 (standard).

The settings can only be configured via the RMS-CONFIG SW and the AC3001 cable.

|