In order to get the normal operation status Green, the following errors have to be resolved:

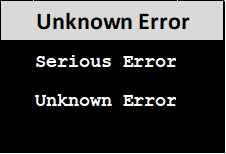

•Serious errors (Serious errors are errors that prevent the regular operation of the device)

•Probe & Sensor errors (Probe errors are errors of the connected probe that must be resolved before the device can resume regular operation)

In case of a serious error, please disconnect the power supply and re power the device again.

If the failure still exist you may get in contact with Support department.

Probe & Sensor error

Probe errors are errors of the connected probe that must be resolved before the device can resume regular operation:

There are different Error indications regarding the connected Probe:

Error message according to NAMUR (Interest Group Automation Technology in the Process Industry)

NAMUR NE43 is a guideline that deals with the standardization of current signals in the range of 4–20 mA.

The NE43 specifies limit values and behaviors for current signals in order to present error messages and diagnostics

in process plants in a clear and standardized manner.

The DAC Outputs react in case of error messages from Sensor and Probe and will generate an upper limit of error over 22mA:

Probe Errors |

||

Error Message |

Description |

DAC Outputs |

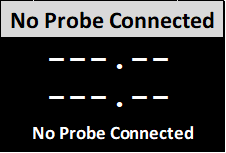

No Probe Connected |

The Probe is not successfully connected |

22.00 mA |

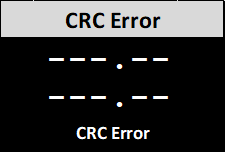

CRC Error |

Communication error between device and sensor data transmission |

22.50 mA |

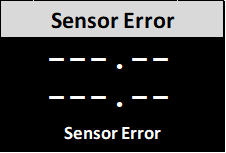

Sensor Error |

Sensor might be damaged (short circuit, disconnection or similar) |

22.25 mA |

Serious Error |

Errors that prevent the regular operation of the device |

23.00 mA |

Example: Sensor Error - When the humidity or temperature sensor is damaged or twisted, the DAC Output will rise up to 22.25 mA.

The safety advantage of the new humidity and temperature transmitter with output monitoring in accordance with NAMUR NE43 lies

in the early detection of sensor faults, such as short circuits or defects. This provides machine manufacturers with the following benefits:

Increased operational safety:

Faulty sensor values are detected by the monitoring function and displayed as an error message before they can affect the process.

This prevents incorrect measurement data from leading to dangerous situations.

Reduction of downtime's:

Direct fault detection allows maintenance measures to be initiated quickly and in a targeted manner, which minimizes unplanned downtime's.

Compliance with safety standards:

Compliance with NAMUR NE43 helps machine manufacturers meet the requirements for safety and reliability in sensitive applications.