Rotronic recommend a maximum interval of 12 months between calibration checks. A small amount of the zero drift can be accommodated by re-zeroing the gas detector against the sensor. The degree of drift that is acceptable should be determined by the user. Note that the subsequent change in gas reading will be greater than the change in zero reading. If the sensor requires either a "zero" or "span" adjustment, the CCA-S-20X-SET is required.

Important: The unit must be powered for a period of 10 minutes before that an adjustment can take place.

Adjustment overview

Adjustment |

|

|---|---|

Functions |

Description |

➢Sensor zero |

Ensure that the sensor is in a zero-gas environment.

NOTE: 1) Carbon dioxide sensors cannot be zeroed in air due to the background levels of CO2 present. These sensors are best zeroed whilst being exposed to 100 % nitrogen. 2) Where a purging gas has to be applied, use a flow rate of between 200 and 600 cc/min. Allow sufficient time for the sensor to respond.

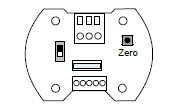

Press the zero button and hold for a minimum of five (5) seconds to zero the sensor.

|

➢Sensor span |

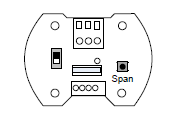

Always zero the sensor prior to performing a span operation.

Apply a known concentration of gas at a flow rate of between 200 and 600 cc/min. Allow adequate time for the sensor to respond.

Press the span button and hold for a minimum of five (5) seconds to span the sensor.

NOTE: 1) The calibration gas level must match with the level stored in the sensor. Refer to the calibration certificate for the calibration gas concentration.

|