Within RMS, a hysteresis can be placed on warning & alarm levels. What exactly does hysteresis mean and what does it do?

Definition: Please see the Collins Online Dictionary for an exact definition, https://www.collinsdictionary.com/di...ish/hysteresis (please see the definition under Electrical engineering that is most relevant for this explanation).

Meaning: In RMS, when a hysteresis is placed on an alarm, the alarm will only switch off once the measured values have crossed back inside the alarm upper or lower limit with hysteresis added.

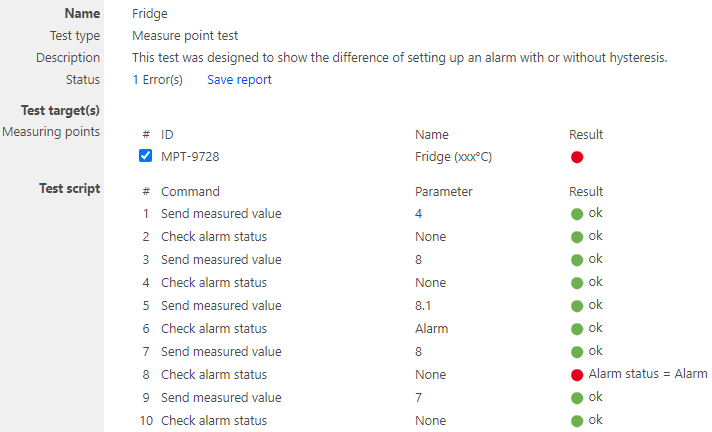

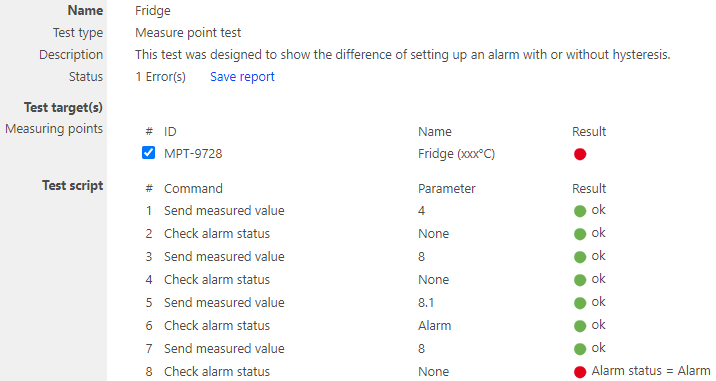

Example 1, no hysteresis:

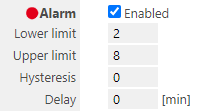

Alarm settings:

When the temperature measurement crosses the lower or upper limit (>8°C or <2°C), an alarm is triggered. When the temperature measurement comes back into an acceptable range (<8°C and >2°C), then the alarm will stop. This is demonstrated in the validation test below:

The validation test shows in position 5, that when the temperature measurement is above the upper limit, then the alarm is triggered (position 6). As soon as the temperature measurement is below the upper limit, see position 7, then the alarm is no longer active as shown in position 8.

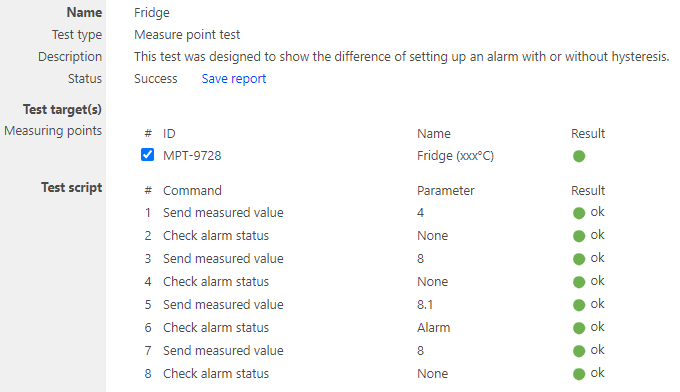

Example 2, with hysteresis:

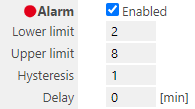

Alarm settings:

When the temperature measurement crosses the lower or upper limit (>8°C or <2°C), an alarm is triggered. However, only when the temperature measurement comes back into an acceptable range, including the hysteresis (<8-1=7°C and >2+1=3°C), will the alarm will stop.

If we run the same validation test as above, the position 8 will show that the alarm is still active:

In order for the alarm to no longer be active, we have to add the "1" value of the hysteresis, so 7 (8-1=7) in order for the alarm to finish: