Qualification/mapping is a study, where the temperature (mainly) distribution within an area is studied, documented and analysed to ensure that the area fulfills the requirements for its intended purpose.

Within RMS, there is a qualification/mapping tool to support area and device characterizations: Tools>Mapping Explained.

For applications that are subjected to the GxP quality guidelines within regulated industries, qualification/mapping is essential to decide where, within an area, testing, production, storage and distribution can be carried out based upon a scientific risk-based assessment, using the results from a mapping study. Further to a mapping study, the design of an area may be improved or simply blocked off for any GxP purpose. Environmental monitoring systems can be installed to ensure that the area complies to the defined temperature limits to ensure patient safety.

Various guidelines exist as to why temperature mapping is required and how it should be carried out. Rotronic AG have followed the requirements below for the analysis of qualification/mapping projects.

•The Area Characterization report is setup around the USP1079 requirements.

•The Device Characterization report is setup around both the NF X 15-150 and DIN 12880 requirements.

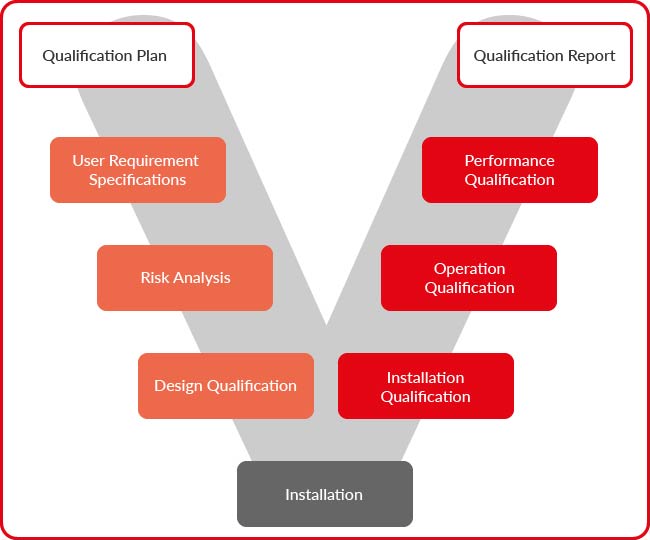

The qualification/mapping process can follow the V model:

•The user requirement specification should state the area/equipment and temperature range required.

•The risk analysis should contain all things that could go wrong with an evaluation of each risk.

•The design qualification should enable the system risks to be decreased.

•The installation qualification checks the area/equipment and all elements that help decrease risks.

•The operation qualification is the mapping with the area/equipment unloaded.

•The performance qualification is the mapping with the area/equipment loaded and/or in summer/winter and can be repeated each year.

Using RMS to carry out a mapping helps comply to certain requirements:

•Rotronic offer a range of USP1118 monitoring devices for time, temperature, relative humidity and CO2.

•FDA 21 CFR Part 11.

•60 second to 15 minute log interval.

•ISO-17025 traceable 3 point calibration with a guaranteed error no more than a ±0.5°C at each calibration point.

•Monitor door openings and power outages.

•Show minimums, maximums, average, standard deviation and mean kinetic temperature.

•Summer /winter mapping and loaded/empty/normal conditions.

•Requirement to map relative humidity/dew point.