The safety of the installed system, where the device is integrated, is the responsibility of the builder of the system.

General wiring guidelines

Power supply wiring

Heavy machinery and instrumentation should not share the same power supply wiring. If this cannot be avoided, noise filters and surge protectors should be used. Most UPS devices have those features already integrated.

General guidelines for signal cables

The following guidelines are derived from European Standard EN 50170 for the transmission of signals by copper wires. When planning an installation, the rules provided by EN 50170 should be followed under consideration of local circumstances to determine the position of machines and equipment.

All ROTRONIC products are tested for Electromagnetic Compatibility according to EMC Directive 2004/106/EG and following European standards:

- EN 61000-6-1: 2001, EN 61000-6-2: 2005

- EN 61000-6-3: 2005, EN 61000-6-4: 2001 + A11

Whenever the level of electromagnetic interference is expected to be high, both the instruments and signal cables should be placed as far away as possible from the source of interference.

In general, signal cables should be installed in bundles or channels / conduits, separate from other cables as indicated in the table below:

•Bus signals such as RS485 •Data signals for PCs, printers etc. •shielded analog inputs •unshielded direct current (<= 60V) •shielded process signals (<= 25 V) •unshielded alternate current (<= 25V) •coaxial cables for CRT monitors |

in common bundles or channels / conduits |

•direct current from 60 V to 400 V (unshielded) •alternate current from 25V to 400 V (unshielded) |

in separated bundles or channels / conduits, without minimum distance / |

•direct and alternate current > 400 V (unshielded) •Telephone lines •lines leading into EX-rated areas |

in separated bundles or channels / conduits, without minimum distance |

Lightning protection

Cabling in areas with a risk of lightning requires a lightning protection. For cabling underground in between buildings, we recommend the use of special fiber optic cables. If this is not possible, use copper cables that are suitable for underground installation.

Cable grip and cable specifications

The HF7 is supplied either with one M16 sealing cable. The M16 cable grip provides effective sealing only with cables having the proper outside diameter. Preferably, use a cable with an outside diameter of 6 to 7 mm (0.236 to 0.275 inch) with 18 AWG wires.

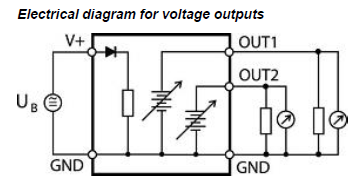

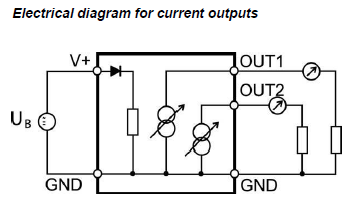

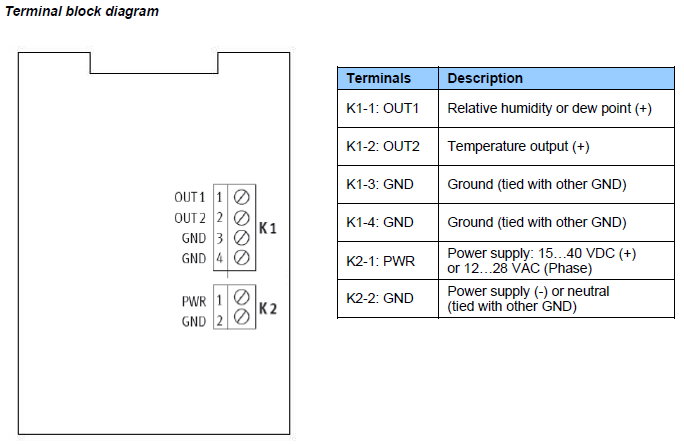

Wiring and terminal block diagrams

HF73: 3-wire transmitter

The maximum permissible cable length can be determined under consideration of the voltage drop caused by the current flowing to the devices connected to the unit. The voltage drop in the cable depends both on cable resistance and on the equivalent resistance of the devices connected in parallel to the unit. The total resistance connected to each unit output should be at least 1000 ohms. Cable resistance should not be more than 1/1000 of the load resistance.

Minimum load requirements apply to the external device or circuit connected to the HF7 transmitter. These requirements are defined in the “Operation” chapter

The maximum permissible cable length, connecting the unit to other devices, is determined by the total resistance resulting from the addition of the cable resistance and that of the devices connected in series with the unit. This resistance should not exceed 500 ohms.

Measuring humidity or temperature only

Operation of the HF73 does not require both current loops to be closed. When using the HF73 to measure either humidity only or temperature only, close only the loop that is being used.

If necessary, any unused output of the HF7 can be disabled with the ROTRONIC HW5 or HygroSoft software.

Grounding

We generally recommend grounding the (-) side of the power supply, especially if the electronics will be subjected to a low humidity environment (35 %RH or less).