HygroMer IN-1 - The perfect Sensor for industrial applications

Industrial - humidity sensor

•Established on the market over 10 years

•Advanced mechanical design and chemical resistance

•Good long-term stability

A capacitive polymer humidity sensor is a special type of humidity sensor based on the use of polymeric materials to detect changes in humidity. The sensors utilize the properties of polymers that react to moisture and thereby influence the capacitance of the sensor. The evaluation electronic convert the capacitive value into humidity value.

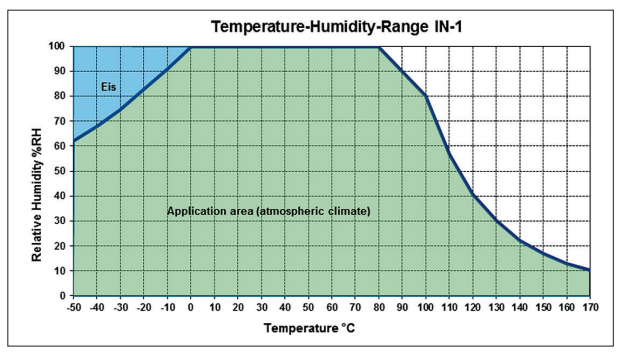

The HygroMer IN-1 sensor stands for Industrial and is considered for measurements with moderate to high temperatures.

Applications

•Pharmaceutical & Food industries

•Industrial high-temperature

•Chemical industries, processes and manufacturing

IN-1 Dimension

|

Innovation in Humidity Measurement•Best long-term stability •Robust mechanical construction •Response time < 15 s •0...100 %RH •-50...170 °C •PTFE surface protection

|

Further Info

|

Functions |

Description |

||||||||||||||||||||

|

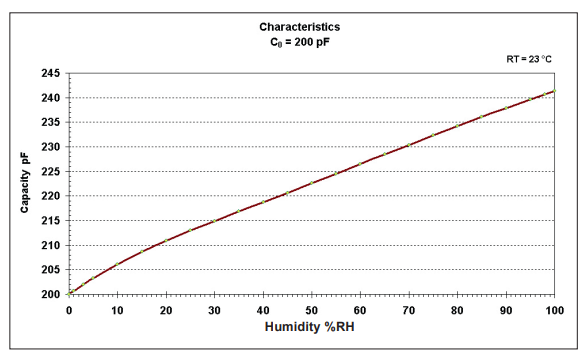

Characteristic polynomial

5th degree polynomial Y = A0 + A1*x + A2*x2 + A3*x3 + A4*x4 + A5*x5

A0 = 2.00000E+02 A1 = 7.12550E-01 A2 = -1.19025E-03 A3 = 2.01789E-04 A4 = -1.59209E-06 A5 = 4.65615E-09 |

||||||||||||||||||||

|

Specifications

|

The shown data are guide values. The resistance of the sensor strongly depends on the temperature and humidity conditions as well as on

exposure duration to the pollutant. Allowed fault caused from the pollutant: ±2 %RH (10…90 %RH).

Pollutant |

Formula |

Max.Workplace Allowed Concentration

|

Allowed Concentration Continuous Operation |

||

|---|---|---|---|---|---|

(ppm) |

(mg/m3) |

(ppm) |

(mg/m3) |

||

Acetic acid |

CH3COOH |

10 |

25 |

800 |

2000 |

Acetone |

CH3COCH3 |

1000 |

2400 |

3300 |

8000 |

Ammonia |

NH3 |

25 |

18 |

5500 |

4000 |

2-Butanone (MEK) |

C2H5COCH3 |

200 |

590 |

3300 |

8000 |

Chlorine |

Cl2 |

0.5 |

1.5 |

0.7 |

2 |

Ethanol |

C2H5OH |

1000 |

1900 |

3500 |

6000 |

Ethyl acetate |

CH3COOC2H5 |

400 |

1400 |

4000 |

15000 |

Ethylene glycol |

HOCH2CH2OH |

100 |

260 |

1200 |

3000 |

Ethylene oxide |

C2H4O |

3 |

3 |

||

Formaldehyde |

HCHO |

1 |

1.2 |

2400 |

3000 |

Hydrochloric acid |

HCl |

5 |

7 |

300 |

500 |

Hydrogen sulfide |

H2S |

10 |

15 |

350 |

500 |

Isopropanol |

(CH3)2CHOH |

400 |

980 |

4800 |

12000 |

Methanol |

CH3OH |

200 |

260 |

3500 |

6000 |

Nitrogen oxides |

NOx |

5 |

9 |

5 |

9 |

Ozone |

O3 |

0.1 |

0.2 |

0.5 |

1 |

Petrol |

300 |

1200 |

150000 |

||

Sulfur dioxide |

SO2 |

5 |

13 |

5 |

13 |

Toluene / Xylene |

C6H5CH3 |

100 |

380 |

1300 |

5000 |

The data in this documentation result from experience and testing. Depending upon site conditions (temperature, dampness, pollutants etc.)

the values can differ. A warranty claim cannot be derived from it.