Overview

To connect the HC2 probe with the PC use the AC3001 cable.

When HW5 has detected a HC2 or HC2A probe, the probe appears as an icon in the left pane of the HW5 main screen. Click on the + sign to the left of the probe icon to display a list of the available functional modules.

Device Manager

The device manager can be opened for any device in the device tree.

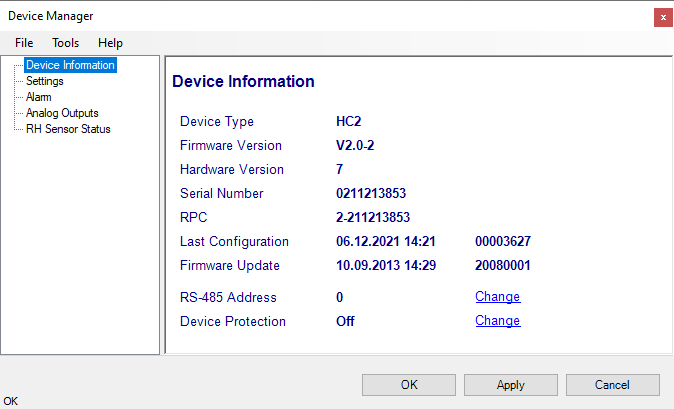

A click opens the following dialog box

Typically, several device properties and settings are displayed and can be set. This information and settings differ from device to device type.

•Device information

•Settings (name, measurement units, fix values etc.)

•Device Manager of the connected probe

•Analog Inputs and outputs (range and scaling)

•Digital Inputs

•Relay

•Ethernet settings

•etc.

For detailed information, please see chapter Devices

Note •Alarm settings can be set in the device, but are not displayed / supported by the HW5 anymore. |

FORGOT THE PASSWORD? - Power down the device. After powering up the device, you have about one minute to use the default password !resume! (include the exclamation marks). After one minute the default password will be no longer accepted.

Device Manager Menu Bar

The Device Manager menu bar is located at the top of the form.

File

The file menu is used to save to the PC, or to retrieve from the PC, the configuration settings of the HC2 probe. The settings are saved in an XML file with the extension DAT. Saving the configuration settings to a file is useful for several reasons:

- provides a backup when the probe configuration has been changed in error

- provides a means of quickly configuring a replacement probe in the exact same manner as the original probe when the original probe is defective

- provides a means of quickly configuring a number of identical probes

Open: opens the device configuration folder specified in HW5 Global Settings - File Locations Tab - and displays all available probe and device configuration files (extension DAT). Select the appropriate file and click on Open in the explorer form. The contents of the configuration file are loaded to the Device Manager form. Review the contents of the Device Manager sub-forms. Click on the Device Manager OK button to write the configuration settings to the probe or click on the Cancel button to leave the probe unchanged.

Save As: saves the current configuration to an XML file with the extension DAT) in the device configuration folder specified in HW5 Global Settings - File Locations Tab. If so desired, any directory and any file type may be specified.

Exit: exits Device Manager

Tools

Firmware Update: This tool is used to update the firmware of the HC2 probe after downloading a new firmware file from the ROTRONIC website to your PC. Firmware files are given a name that shows both to which device the file applies and the version number of the firmware. All firmware files have the extension HEX or ROF. The ROTRONIC website will publish firmware updates as required. The tool opens a form that allows you to specify the folder where the firmware update file is located and to select the file. Click on OPEN to start the update process.

IMPORTANT: the probe must be powered during the entire process. Loss of power when the probe is being updated may have unexpected results and prevent future operation of the probe.

Generate Protocol: generates a Device Configuration Protocol. This text file is automatically saved in the folder specified in HW5 Global Settings - File Locations Tab. If so desired, any directory and any file type may be specified. This action is not recorded in the User Event file.

Communication Protocol: This tool is provided for users who want to digitally communicate with the

HC2 probe digital interface without relying on the HW5 software and is used to select and configure one of the available communication protocol options.

Protocol Type: Select from one of the following options: RO-ASCII: This is the standard (default) communication protocol used by the HC2 probe and by the HW5 software.

Custom: This communication protocol can be used to provide compatibility of the HC2 probe with an existing communication system. The Custom communication protocol is limited to reading measurement data from the probe. Functions such as device configuration, humidity and temperature adjustment, etc. are not supported. The Custom protocol allows RS-485 networking (when the probe is connected to the appropriate digital interface cable)

Modbus: Use of the Modbus protocol is limited to devices with a RS-485 interface. The AirChip 3000 Modbus protocol is limited to reading measurement data from the AirChip 3000 device. Functions such as device configuration, humidity and temperature adjustment, etc. are not supported by the AirChip 3000 Modbus protocol.

I2C: Use of the I2C protocol is limited to HC2 probes and to some OEM products. The I2C protocol available with the AirChip 3000 is limited to reading measurement data. Functions such as device configuration, humidity and temperature adjustment, etc. are not supported by the I2C protocol

Unsolicited Mode:

Selecting this mode causes the HC2 probe to send data automatically after each refresh cycle without requiring a data request. This is the only mode available with the I2C protocol.

NOTES:

The Custom, Modbus and I2C protocols can be used only with AirChip 3000 devices with firmware version 1.3 or higher.

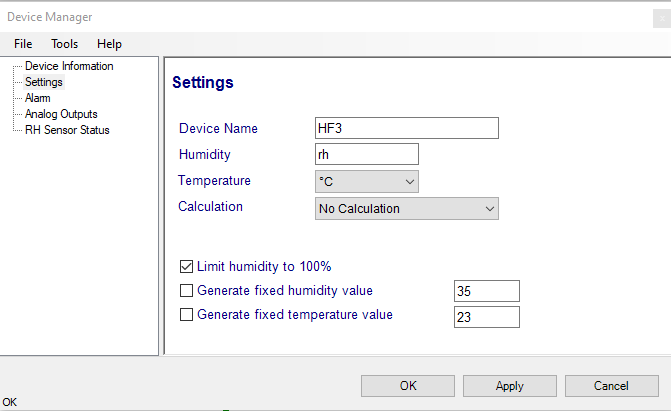

Settings

Device name: As far as possible use a unique device name (maximum 12 characters).

Humidity: Possibility to change the abbreviation of the relative humidity, which is different in other languages.

Note: It can only have max. 2 digits

Temperature: Changing the unit of the Temperature from Celsius to Fahrenheit.

Calculation: Adding a third parameter. Dew point (Dp), Frost point (Fp) etc. (depends on the device).

Limit humidity to 100%: typically, the humidity sensor gives a reading slightly above 100 %RH when condensation occurs at the surface of the sensor. Check this box to limit the maximum value of humidity to 100 %RH.

Generate fixed humidity/temperature value: place a check mark in these boxes to make the HygroFlex generate fixed humidity and temperature values instead of the actual measurements.

The fixed values must be with the following limits: -999.99 and 9999.99.

Note: Make sure that the fixed values fall within the range specified for the HygroFlex analog outputs. Using the device as a simulator serves the purpose of verifying the analog signal transmission (loop validation) after completing an installation.

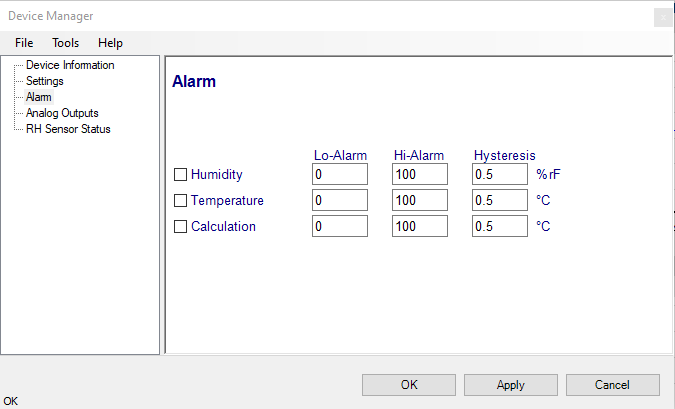

Alarm

Note: This function has no effect on the device analog outputs and applies only to the transmitter optional display (an alarm symbol appears). The digital communication with a PC via service connector or permanent digital interface will not work anymore with the HW5.

Alarm conditions can be defined for humidity, temperature and the calculated parameter. Values that are below the low alarm value or above the high alarm value will trigger an alarm. The value specified for the alarm function hysteresis is used for both the low and the high alarm.

All versions of HW5 will show an out-of-limits value alarm in red on the monitor screen. In addition, HW5 can be configured (HW5 global settings - Alarm settings tab) to display an alarm table and generate a report whenever an out-of-limits condition occurs.

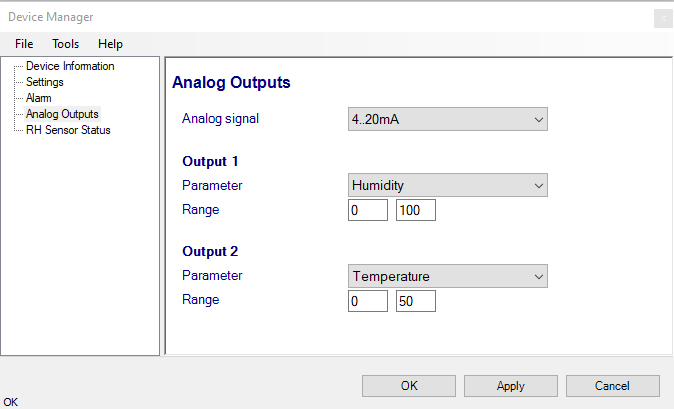

Analog Outputs

Analog signal: Analog signal: the type of signal cannot be changed and is always 0…1V

Output 1 and Output 2: select the parameter corresponding to each analog output and the range to be used.

Each output can be made to correspond to the parameters shown on the list. Any output can also be disabled. The output range must be within the numerical limits of -999.99 and 9999.99

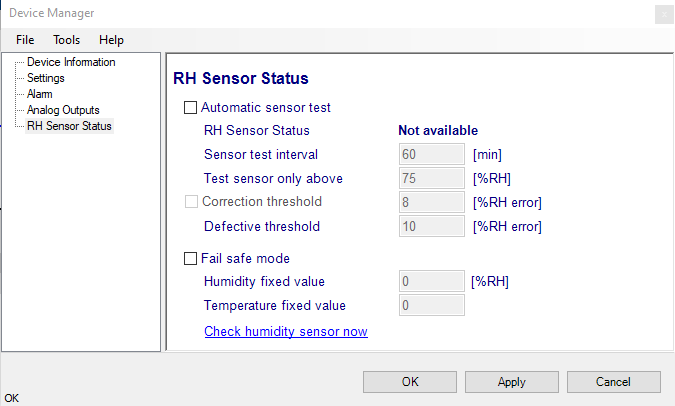

RH Sensor Status

Automatic Sensor Test: place a check mark in this box to enable the automatic RH sensor test.

Sensor Test Interval

Enter the desired time interval for the automatic sensor test (minutes). Recommended value: 60

Test sensor only above

The RH sensor will be tested only when the measured humidity value is equal to or higher than the value entered in this text box.

Default value: 60 (may be changed by factory)

Note: a different test is used to detect major sensor problems such as an open circuit or a short circuit. This test is not affected by the settings entered in this form.

Depending on the test result, the RH sensor status is reported as follows:

Not available

The sensor has not been tested. Verify the RH sensor test settings (Device Manager menu bar > Tools). The sensor will not be tested as long as the current value of %RH is below the value entered in the box labeled “Test above [%RH}”

Good

The sensor error is less than the correction threshold value. The correction offset (SQ) for sensor drift correction is automatically set to zero

SQ-Tuned

The sensor error is equal or larger than the correction threshold value but less than the defective threshold. A correction (SQ) is automatically added to the value measured by the sensor. The correction (SQ) is calculated based on the %RH currently measured by the sensor and on the coefficients A, B and C (RH sensor test settings).

Bad

The sensor error is equal or larger than the defective threshold value

The AirChip 3000 issues a digital alarm only when both of the following conditions are met: (a) the %RH measured prior to the test is at least equal to the value entered in Tools > RH Sensor Test Settings > Test above [%RH] box and (b) the humidity sensor test returns the result “Bad”. When using HW5 to communicate with the HF3/4 transmitter, the text “Bad Sensor Alarm” appears in red on the monitor screen. HW5 Professional can be configured (HW5 global settings - Alarm settings tab) to display an alarm table and generate a report whenever a device alarm condition occurs.

Correction Threshold: place a check mark in this box to enable the automatic RH sensor drift compensation function.

Correction Threshold

Enter the sensor error (%RH) that will trigger a correction. Recommended value: 2 (may be changed by factory)

Defective Threshold

Enter the sensor error (%RH) above which the sensor will be considered to be defective. Recommended value: 5 (may be changed by factory)

Fail Safe Mode: In the event of a sensor failure, this function makes the HF3/4 generate predetermined humidity and temperature values so as to prevent undesirable action by a humidity or temperature control device that relies on the analog or digital signals of the transmitter. Place a check mark in this box to have the HF3/4 generate a fixed humidity or temperature value (both digital and analog) when any of the following occurs:

•RH sensor test returns the result “Bad”

•Major failure of either the humidity or temperature sensor (shorted or open sensor)