Calibration is the only way to prove instrument performance. By comparing an instrument against a known reference at several stable conditions we can asses what error exists. Over time we can assess the instruments drift and repeatability. Once errors are know they can be corrected for or adjusted out.

Regulatory requirements within GxP applications require calibrated devices. The regulations are limited in terms of explaining what calibration is required. Rotronic recommends adopting a risk based approach considering the application, interval and type of calibration:

•ISO9001 Factory Calibration: https://www.rotronic.com/en-ch/humidity_measurement-feuchtemessung-mesure_de_l_humidite/mobile_calibration_lab-kalibriermobil-mr

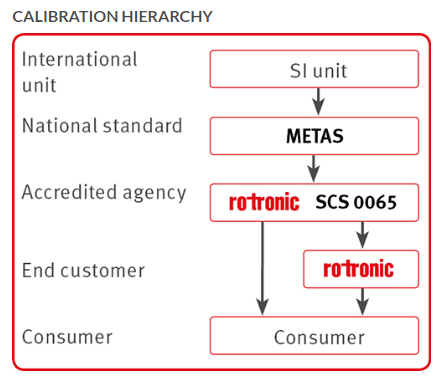

•ISO17025 Traceable calibration: https://www.rotronic.com/en-ch/humidity_measurement-feuchtemessung-mesure_de_l_humidite/scs_calibration-scs_kalibrierstelle-mr.

ISO17025 calibration is performed with a laboratory that is regularly audited to ensure compliance to strict standards. All ISO17025 laboratories have defined measurement uncertainties and regularly perform inter-comparisons with other laboratories to ensure performance.